IoT for businesses

The Internet of Things (IoT) and the Industrial Internet of Things (IIoT) are essential aspects of the ongoing digital revolution. IoT and IIoT are terms you've probably heard before, and you may already be using some of these technologies. Organizations can increase productivity, make better decisions, and generate new revenue streams by utilizing the Internet of Things and the Industrial Internet of Things (IIoT).

What is IoT, and how does IoT work?

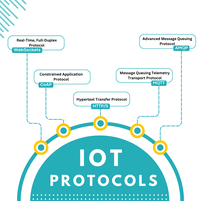

Devices in the Internet of Things (IoT) communicate with one other and offer data to consumers over the Internet, creating a network. A single IoT device can be helpful, but when used in conjunction with other devices, they become even more useful.

The Internet of Things (IoT) is expanding as more and more devices can connect to it. The Internet of Things (IoT) includes a wide range of instruments. Manufacturing equipment, electrical substations, buildings, and infrastructure, all of which are becoming increasingly interconnected, can all be included. The Internet of Things is utilized by many companies and organizations today (IoT).

How much energy is used in a building's lights or how much water flows through a wastewater treatment facility can be automatically collected with IoT technology. The data collected by IoT systems and devices can be sent to a central system over the Internet. Using this data, managers can make better judgments. It's possible to gain new insights and forecast future outcomes by employing various data analysis techniques.

Equipment and aspects of your operations can be automated using IoT technology. It is possible for equipment equipped with sensors to automatically modify its operation to reduce energy consumption and improve traffic flow and other factors. When they detect a specific input, sensors that are "smart" take action or send a signal to take action are called "smart sensors." When the sensors detect movement, the lights switch on. As a result, operators can be alerted to possible hazards via smart sensors.

What is IIoT, and how does IIoT work?

IIoT is a subset of IoT. In the context of the manufacturing industry, the term "industrial IoT" refers to implementing Internet of Things (IoT) technology. Next-generation manufacturing will be enabled by IIoT, which is a critical component of Industry 4.0. Technology, data, automation, interconnection, and artificial intelligence (AI) are all part of Industry 4.0, which focuses on using these technologies in the workplace. As a result of these advancements, factories and other industrial establishments are experiencing a paradigm shift.

Many of the potential applications and advantages of IIoT are similar to those of IoT. Sensors for industry, energy, and infrastructure can be integrated with smart sensors. They can assist industrial companies in improving efficiency, productivity, and employee safety by collecting data and enabling additional functionality through these sensors.

Plant managers can better understand their facility's operations thanks to the IIoT, which improves communication between machines. By collecting detailed data over time, industrial firms may better monitor their use of energy, water, and other resources, as well as when and how much they produce. It's up to the operator to make manual changes, or the equipment can do it for them automatically.

Companies can save considerable energy, water, and other resources while boosting or sustaining productivity with this ongoing optimization. Lean manufacturing can be achieved using the Industrial Internet of Things (IIoT). In addition, IIoT can be used to gather data for predictive maintenance programs, speed up product development, and accomplish other business objectives.

What are the benefits of IoT and IIoT in business?

Manufacturers, towns, and other end users can make all profits from IoT and IIoT technology. These are some of the advantages:

Improved efficiency:

The Internet of Things (IoT) can gather data in real-time regarding the machinery, procedures, and resources utilized by a machine, system, or structure. Inputs for industrial processes such as water, natural gas, electricity, and other forms of energy fall into this category. You may lower your consumption and increase your output by better understanding how you consume resources and manage your operations. You may cut costs and improve your company's overall performance and productivity by increasing efficiency.

Reduced downtime:

You can reduce equipment downtime by allowing predictive maintenance and alerting personnel to concerns early. This can save businesses a lot of money while ensuring communities have constant access to water, electricity, and other essential resources. Using an Internet of Things (IoT)-enabled predictive maintenance software can help you avoid more severe damage to your equipment, reducing your overall maintenance costs and saving you money.

Remote control:

You can control your equipment from anywhere worldwide as long as you have an Internet connection and the appropriate software. Handling equipment might be as simple as setting a timer or as complex as programming it to respond automatically to changing conditions. It is easier to respond to the evolving requirements if you can control your equipment remotely.

An improved sense of safety:

Connecting your infrastructure to the Internet can give additional security, but remote control of machines or infrastructure presents some genuine dangers. Protecting your firm from illegal access and data loss is easier if you use devices and software that have integrated security safeguards. It is possible to reduce risk and manage your data and equipment more effectively with high-security encryption, secure authentication, and customized administration choices.

Better decision-making capabilities:

Smart sensors can help you collect more data and provide a greater degree of information. Even if you don't use big data analytics to get the most out of this data, you can still get some value. You can make better judgments based on this information and the insights you gain. You can also use your data to predict future events and prepare for them based on what you've learned from them.

Increased Return on Investment:

Improve your company's bottom line and return on investment with the help of IoT and IIoT. It can help you save money in various ways, including by improving energy efficiency and predicting maintenance needs. You can keep your firm ahead of the competition and avoid risk by making better decisions and predicting future outcomes.

Conclusion:

There will be a steady rise in IoT and IIoT technologies over the next few years. By 2025, the world's connected gadgets will be 30.9 billion. According to industry estimates, the IIoT market will be worth USD 1.1 trillion by 2028. These technologies have already had a considerable impact in various fields, including healthcare, industry, and consumer products.

Together with other Industry 4.0 technologies, they will continue to drive digital transformation and substantially impact practically every sector. The Internet of Things (IoT) and the Industrial Internet of Things (IIoT) have the potential to make even more of an impact when combined with sophisticated technologies like automation, data analytics, artificial intelligence, and others.

IoT and IIoT can assist organizations in getting an advantage over their rivals in their respective industries. Businesses increasingly rely on these technologies to prevent falling behind their competitors, and their importance will only grow in prominence over the next few years.

Next Steps

Explore more

Need any help in IoT?

Need any help in IoT? An Atreyo expert identify the right solution for your needs.

If ready to talk to an Atreyo expert

Interested in IoT products? go to